Production

1. Procurement of Raw Materials

2. Employment of Advanced Manufacturing Techniques

3. Implementation of Quality Control Measures

1. Procurement of Raw Materials

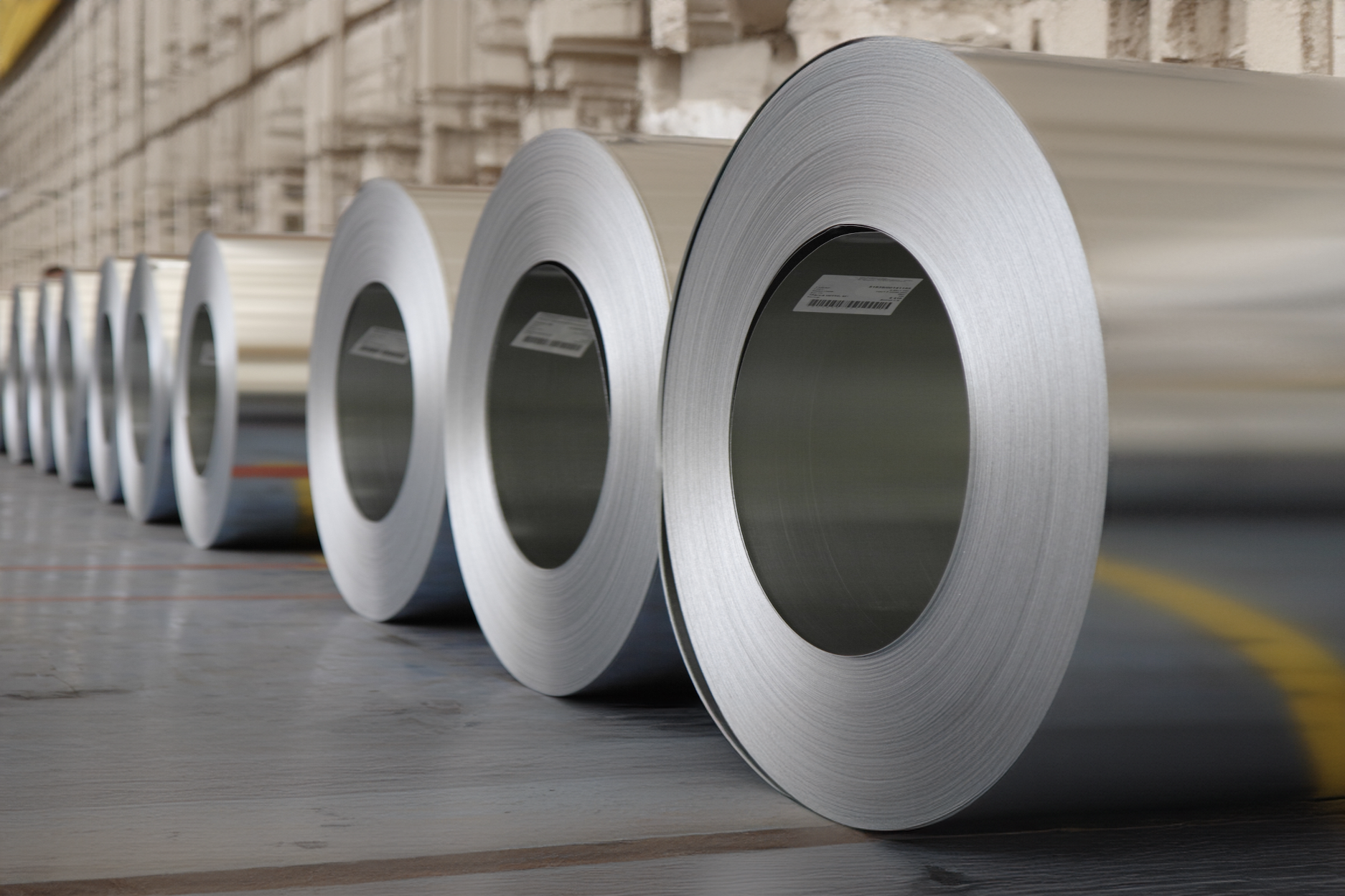

This stage involves sourcing essential materials such as stainless-steel sheet, galvanized steel and other corrosion-resistant materials.

The selection of these materials is crucial to ensure the durability and longevity of the final product, especially in environments prone to high temperatures and corrosive elements.

2. Employment of Advanced Manufacturing Techniques

Once the raw materials are acquired, advanced manufacturing techniques are employed to shape and assemble the flue components.

Techniques such as laser cutting, plasma cutting, bending, rolling, and welding are utilized to fabricate the components with precision and accuracy. These techniques allow for intricate designs and complex shapes to be achieved, meeting the exacting specifications required for optimal performance.

3. Implementation of Quality Control Measures

Throughout the production process, rigorous quality control measures are implemented to maintain high standards and ensure the reliability of the final product.

Dimensional inspections are conducted to verify that each component meets the specified measurements and tolerances. Material testing is performed to assess the mechanical properties and integrity of the materials used. Additionally, surface finishing processes such as polishing or coating may be applied to enhance aesthetics and protect against corrosion. These quality control measures are essential to uphold consistency and compliance with industry standards, ultimately guaranteeing the reliability and performance of the flue components.

Need a Flue?

We’ll Help You!