Design & Measurements

In the realm of precision design, engineers carefully plan the dimensions and materials

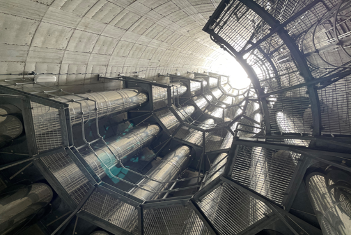

Flues serve the purpose of safely discharging flue gases, smoke, or other airborne pollutants from any combustion processes to the outside environment. Whether in residential, commercial, or industrial settings, precision in designing and measuring flues is paramount for ensuring safety, efficiency, and compliance with regulatory standards.

In the realm of precision design, engineers carefully plan the dimensions, materials, and configurations of flues to optimize their performance. Factors such as the type of fuel being used, the temperature and velocity of the exhaust gases and the surrounding environmental conditions all influence the design considerations.

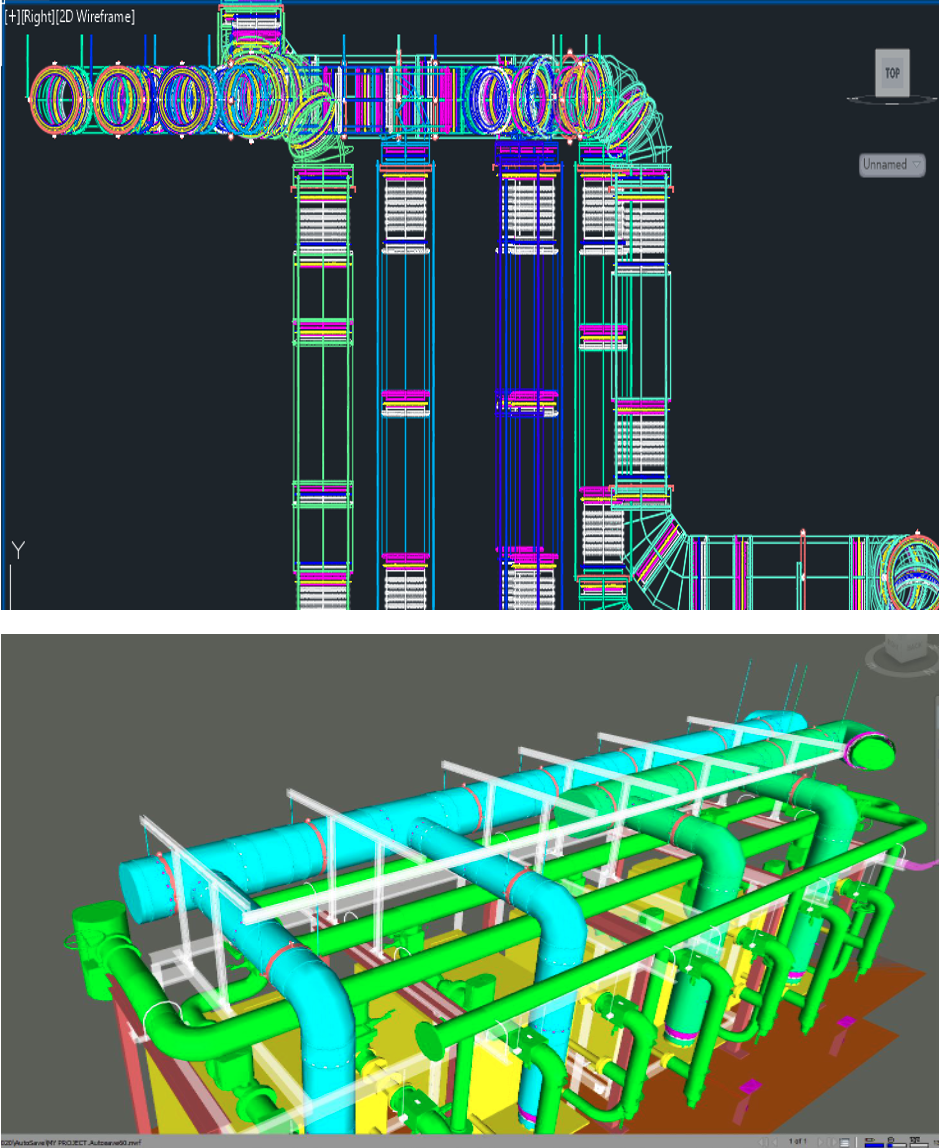

Advanced computer-aided design (CAD) software enables engineers to create detailed drawings that account for thermal expansion, structural integrity, and efficiency of the appliances, ensuring that the flue functions reliably under varying operating conditions.

Precision design and measurements are fundamental principles in the engineering and maintenance of flues, ensuring their safe and efficient operation in diverse applications.

By leveraging advanced design tools and measurement techniques, engineers and technicians can uphold the integrity of flue systems, mitigate risks, and promote environmental sustainability in heating and industrial processes.

Crucial Role of Precision Measurements in Flue Fabrication and Installation

Precision measurements play a critical role throughout the lifecycle of a flue, from fabrication and installation to maintenance and inspection.

During fabrication, accurate measurements ensure that components such as flue liners, connectors and support structures are manufactured to exact specifications, minimizing leakage and maximizing airflow. During installation, precise measurements ensure proper alignment and connection of flue sections, seals and support brackets, preventing leaks and minimizing the risk of structural failure.

Regular maintenance and inspection of flues also rely on precise measurements to assess their condition and performance. Techniques such as smoke tests, airflow measurements, thermal imaging and CCTV, enable engineers to identify issues such as blockages, leaks, or corrosion that could compromise safety or efficiency.

By conducting thorough inspections and measurements, operators can proactively address potential problems, extend the lifespan of the flue and ensure compliance with regulatory requirements.

Need a Flue?

We’ll Help You!