DELTAVENT US

TWIN-WALL FLUE SYSTEMS

Construction

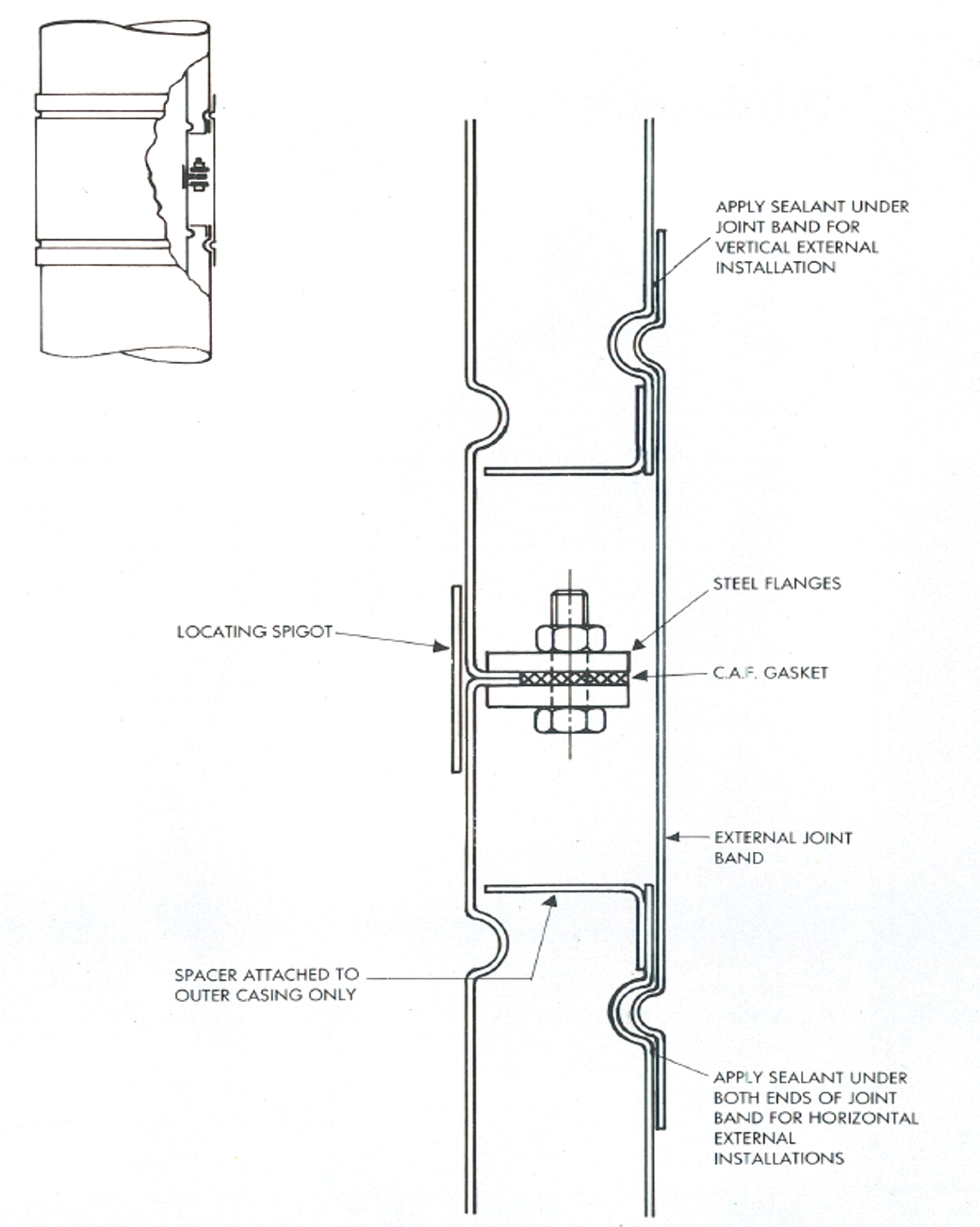

Ultraseal sectional lengths/fitting components are fabricated in a variety of diameters and lengths with continuously welded vertical seams. The Ultraseal system also utilises four insulated/non-insulated annular variation options to ensure the required maximum external case surface temperature is not exceeded. Inner liner coupler characteristics consist of male and female connection sockets complete with a 6mm x 30mm angled flange formed at either end of all components. Ultraseal joints shall be secured by a 30mm flange of the adjoining components.

Diameter RANGE

This double-lined system is available as Deltavent 50 (with a 50mm insulating gap)

There are also 75mm and 100mm annuli available on request.

INT DN Std . 100, 125, 150, 200, 250, 300, 350, 400, 450, 500, 550, 600, 650, 700, 750, 800, 850, 900, 950, 1000,

(On Demand ) 175, 225, 275, 325, 375, 425, 475, 525, 575, 625, 675, 725, 775, 825, 875, 925, 975,

Quality Assurance

The complete range of components are manufactured, tested, and where required, installed within scope of stringent quality

controlled conditions in accordance with EN ISO 9001:2015 and BS EN 1856-1/2:2009. When requested, A1 Flue Systems shall submit copies of type test reports relating to product performance in addition to the “Certificate of Registration” administered by the British Standards Institute.

Fire Rating

The Deltavent US system has been successfully assessed by the Loss Prevention Council for Fire Resistance. A fire rating of 4 hours can be achieved in accordance with stability and integrity criteria of BS 476: part 20. If required, A1 Flue Systems shall submit all test reports in support.

APPLICATION EXAMPLES INCLUDE:

Different grades of stainless-steel dependent on use include 304, 316, and 310

- High pressure Diesel generator exhausts

- High pressure CHP systems

- Incinerators/cremators

- Cryogen Quench Systems

- Low -temperature exhaust/duct extract

- Free standing applications up to 4m

Performance Designations:

- BS EN1856-1 T600-H1-D-Vm-L20070-G (50)

- BS EN1856-1 T600-H1-D-V2-L50070-G (50)

- BS EN1856-2 T600-H1-D-Vm-L20090-G (50)

- BS EN1856-2 T600-H1-D-V2-L50090-G (50)

- BS EN1856-1 T200-H1-W-Vm-L20070-0 (50)

- BS EN1856-1 T200-H1-W-V2-L50070-0 (50)

- BS EN1856-1 T200-H1-W-Vm-L20090-0 (50)

- BS EN1856-1 T200-H1-W-V2-L50090-0 (50)

Application

The Deltavent system has been successfully assessed by the Loss Prevention Council for Fire Resistance. A fire rating of 4 hours can be achieved in accordance with stability and integrity criteria of BS 476: part 20. If required, A1 Flue Systems shall submit all test reports in support.

Combined Heat & Power

Combined heat and power (CHP), also known as cogeneration, is a highly efficient power plant that generates heat and power simultaneously.

Cryogen Quench Pipe

We have decades of experience in the design, manufacture and installation of flues, exhausts, flue dilution and extract systems. This also includes Quench pipes for MRI machines.

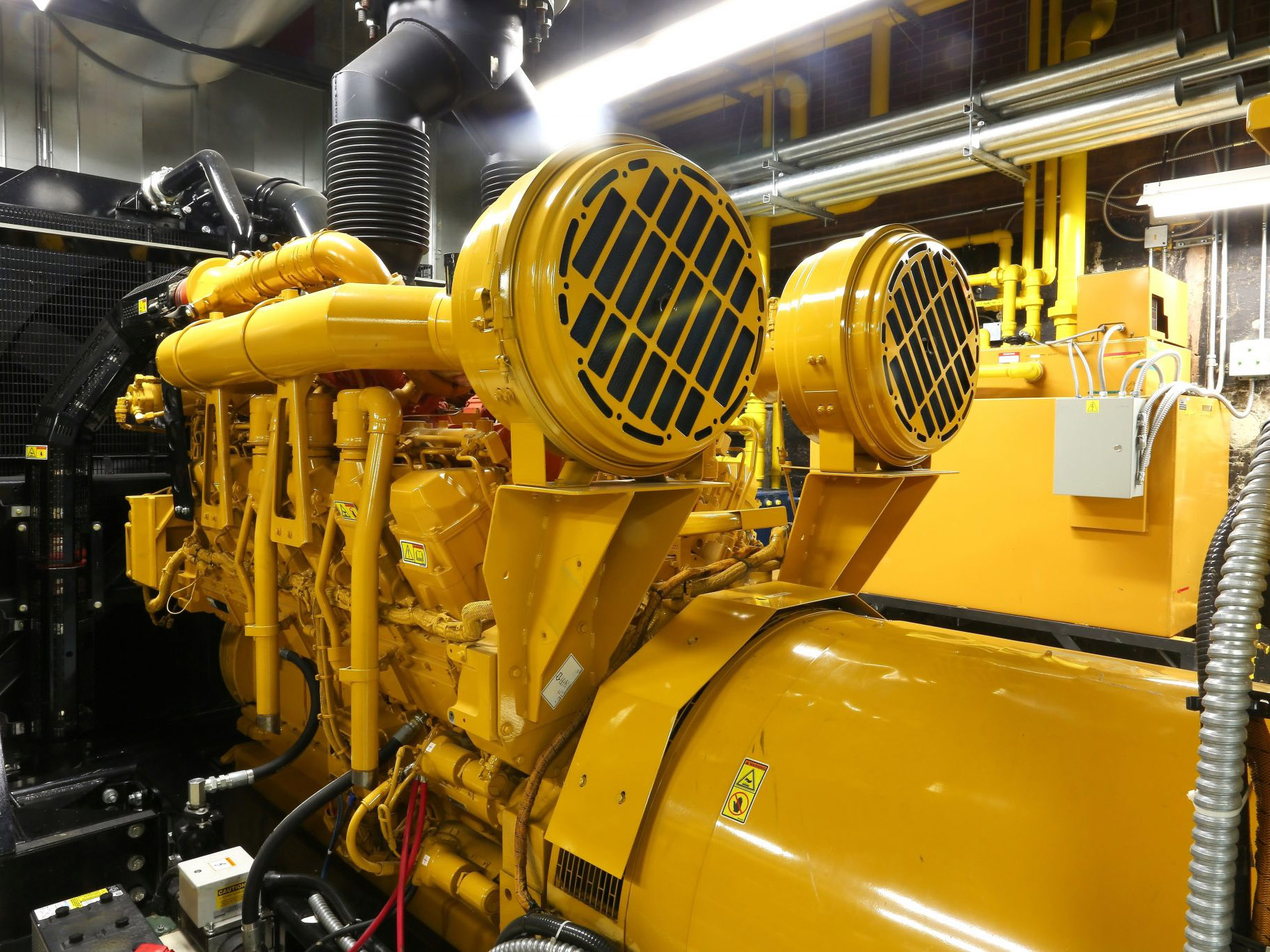

Standby Generators

Automatic standby generator systems may be required by building codes for critical safety systems such as elevators in high-rise buildings, fire protection systems and standby lighting.

Diesel Generators

Some applications require the diesel generator to accept a high impact load, with minimal voltage and frequency deviations in the event of a power loss.

Literature

Deltavent US - 0086-CPR 742990 - 1

View

Deltavent US - 0086-CPR 742991 - 1

View

Deltavent US - BSRIA Report

View

Deltavent US - Twinwall Deltavent US Product Catalogue

View

Deltavent US - Ultraseal Specification Sheet

View