Fan Dilution Systems

Ventilation Installation

Flue dilution fans

Lorem Ipsum

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Morbi id orci sed libero suscipit blandit ut et erat. Ut cursus nisi nunc, hendrerit tempor nisi pharetra in. Fusce enim ligula, fermentum sit amet aliquam eu, volutpat a sem. Quisque laoreet nec urna ut scelerisque.

Lorem Ipsum

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Morbi id orci sed libero suscipit blandit ut et erat. Ut cursus nisi nunc, hendrerit tempor nisi pharetra in. Fusce enim ligula, fermentum sit amet aliquam eu, volutpat a sem. Quisque laoreet nec urna ut scelerisque.

Ventilation Installation

Historically, fan dilution flue systems have only been considered as a last resort when conventional means of exhausting waste gas products have been eliminated or discounted – but all that is changing.

At A1 Flue Systems, our 45 years of experience manufacturing industrial flue and chimney systems for virtually every boiler specification on the market means we now apply the same knowledge to the manufacturing of fan dilution systems.

Because we are able to specify the correct type of fan and determine its functionality, relative positioning system resistance and the noise criteria that need to be applied during its specification, we can design a complete flue or chimney system.

This knowledge and our bespoke manufacturing capability combine to enable us to meet the design specification requirements of most architects and designers, as well as ensure that the visual appearance of the fan fits in with any external building facade requirements.

Flue Dilution Fans

Flue dilution fans are an ideal solution for commercial flue and chimney installations where space is minimal and height is a problem.

They have been specifically designed to handle the exhaust gas products from all types of gas-fired boilers, including fully condensing types.

Flue dilution fans can be set to meet varying load demands (applicable to the relevant plant output) whilst at all times complying with the discharge requirements of 1% CO2, as laid down in the Clean Air Act Memorandum and IGE UP/10.

As contractors and installers have come to expect of A1 Flue Systems, our flue dilution fans are manufactured using high-grade stainless steel and are designed to be totally watertight.

The integral invertor allows for fully programmable step sequencing for varying boiler loads. This makes it one of the most energy-efficient flue dilution units available, creating a 60% improvement in energy efficiency.

A typical unit is extremely compact, extending less than one metre into the plant room (assuming a minimum external wall thickness of 150mm).

The external 750mm x 750mm combined discharge louvre and air intake extends only 250mm from the outside face of the wall.

Flue Dilution Fans with Customizable Exterior.

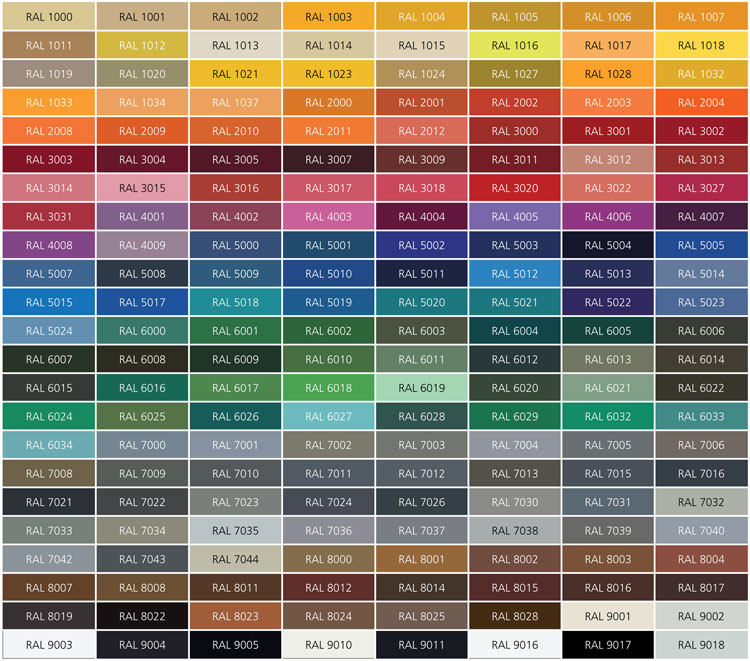

In instances where aesthetic integration is essential, the external component of the flue dilution fan unit offers the option for powder paint coating in a spectrum of RAL colors, ensuring seamless blending with the surrounding environment.

This customization feature incurs a minimal additional expense, providing flexibility in design while maintaining optimal functionality.

Need a Flue?

We'll Help You!