Draught Stabilisers

Ventilation

Installation

Chimney Draught Stabilisers

Draught

breaks

Lorem Ipsum

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Morbi id orci sed libero suscipit blandit ut et erat. Ut cursus nisi nunc, hendrerit tempor nisi pharetra in. Fusce enim ligula, fermentum sit amet aliquam eu, volutpat a sem. Quisque laoreet nec urna ut scelerisque.

Lorem Ipsum

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Morbi id orci sed libero suscipit blandit ut et erat. Ut cursus nisi nunc, hendrerit tempor nisi pharetra in. Fusce enim ligula, fermentum sit amet aliquam eu, volutpat a sem. Quisque laoreet nec urna ut scelerisque.

Importance of Draught Control in Heating Systems

The consequences of an unstable draught are lower efficiency, incomplete combustion and breakdowns.

This is why keeping a draught constant during the entire heating process is important to ensure optimal combustion – variations in the draught can depend on differences in temperature, as well as wind conditions.

It’s also important to note that the management of draughts is important, regardless of whether boilers and CHP units use oil, gas or other solid fuels.

Modern appliances require much more sensitive control of excess draught:

A1 Flue Systems has developed a draught break system that offers complete controllability – irrespective of the number of appliances connected into a single header system.

Condensing appliances are particularly sensitive to excess draughts, so draught stabilisers are especially ideal when condensing appliances are incorporated into flue dilution systems.

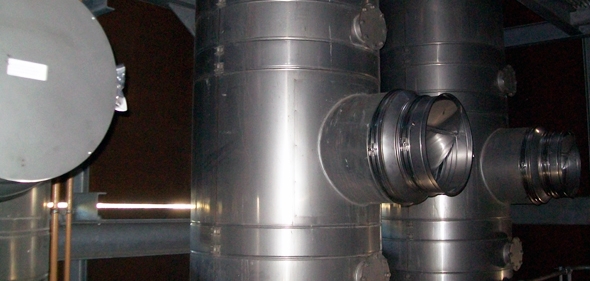

Chimney Draught Stabilisers

A chimney draught stabiliser is a device fitted to a commercial flue system to control the draught of the system to a specific level:

They are essential as a stable draught is important to ensure optimal combustion – irrespective of whether you use oil, gas or other solid fuels.

They comprise a counterweight and a pivoted blade that opens under the difference in pressure on each side of the blade to allow diluted air to enter the flue system.

The introduction of the colder air reduces the flue gas temperature and the flue system’s natural buoyancy; it also increases the flue gas mass flow and the flue system flow resistance to a point where the system’s operating pressure is maintained at around the specific value.

In commercial chimney systems, the stabiliser is set up with a draught gauge and by adjusting the counterweight by trial and error. This is done at the boiler commissioning stage by the boiler commissioning engineer.

The features of our chimney draught stabilisers include:

- All stainless steel

- Corrosion resistant

- Easy to install

- Low maintenance

- Suitable for oil and gas boilers – and condensing boilers

- Meet single- or multi-burner requirements

- Ex-stock delivery

- Special sizes quickly made to order

For technical help on chimney draught stabilisers, either email our Technical Department at technical@a1flues.co.uk or call 01623 867303.

Draught Breaks

The inclusion of draught breaks within commercial flue systems will make a significant contribution to the performance and efficiency of CHP systems.

In the vast majority of installations, the introduction of a draught stabiliser as a draught break is required to maintain the desired draught in an appliance by automatically reducing the draught to the desired value.

In commercial flue and chimney systems, draught stabilisers are required for multiple appliances where the operating conditions change depending on the number of appliances operating at any time.

Fitting a separate stabiliser on each appliance flue pipe is best if space permits.

Alternatively, a single stabiliser can be fitted beyond the boiler connections on the side of the header or at the base of the vertical riser (provided it is within the boiler room). Fitting a stabiliser at the end of the common header is also possible but should not be referred to either of the previous locations.

Did you know we also manufacture a range of explosion relief values for use with biomass appliances?

Need a Flue?

We'll Help You!