Cryogen Quench Pipe

Quench pipes are used in MRI machines to help prevent the formation of dangerous magnetic fields:

The quench pipe is installed between the magnet and the quench vent and works by dissipating the energy from the magnetic field.

This helps to prevent the formation of a quench, which is a sudden release of energy that can cause damage to the equipment and potentially injure patients or staff members.

QUENCH PIPES ARE AN ESSENTIAL SAFETY FEATURE IN MRI MACHINES AND ARE REQUIRED BY LAW IN MANY JURISDICTIONS:

They are also used in the manufacturing process for MRI machines, and they are used during installation to ensure that the machine is properly calibrated.

The pipes play an essential role in ensuring the safety of patients and staff members, and they are an important part of any MRI machine

What happens during a quench?

As the magnet loses its superconducting capacity, the cryogens immediately begin to boil and expand inside the cryostat. The expanding cryogens increase the pressure and temperature until, in a matter of seconds, the pressure-relief valve gives way. The expanding cryogens erupt from the cryostat into the quench pipe, continuing their dramatic expansion as they barrel through the pipe to the discharge point.

Should there be a failure of that pipe at any point in that path of travel, cryogens will burst through into the building. If there is a significant obstruction, the pressure will keep building until it ruptures the pipe or breaks a joint, potentially dumping hundreds of thousands of liters of gaseous helium into the room.

Fortunately, quenches are very infrequent. However, this infrequency has bred complacency, and as a result, many facilities don’t give their cryogen vent a second thought after it is installed.

When three MRI systems were intentionally quenched during Hurricane Katrina in 2005, one of the three quenched magnets ruptured the quench pipe. The pressure buildup in the magnet room exploded the control room window, demonstrating the force of expanding cryogens. While this limited example is not common, it’s important to make sure your installation has been done correctly.

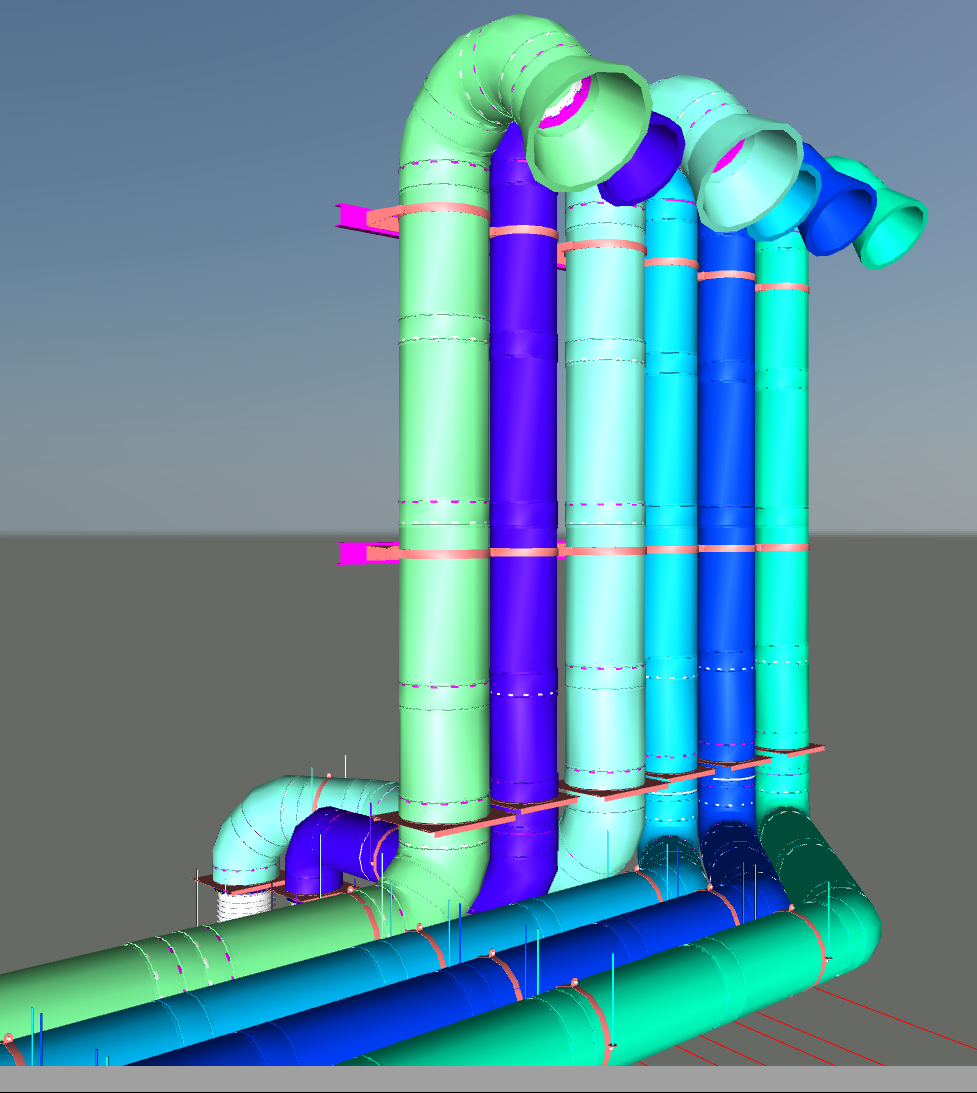

Suitable Products

Deltavent US Twin-wall Flue Systems

Deltavent US high pressure twin-wall flue system that is used in in both high and very low temperature installations where the reduction of hot / cold transfer from the omission of gases inside a flue to the external environment is required.

This double-lined system is available as Deltavent 50 (with 50mm mineral wool insulation). There are also 75mm and 100mm annuli available on request.

The complete range of A1 Flue Systems’ Deltavent chimney products has been successfully tested by B5476 Part 20 for stability and integrity during a four-hour fire test. They have also been UKCA and CE Marked by British Standard (BS)1856

Need a Flue?

We'll Help You!